Some Known Details About Motorcycle Parts New Zealand Specialists

Table of ContentsRumored Buzz on Motorcycle Parts New Zealand SpecialistsThe Motorcycle Parts New Zealand Specialists Ideas6 Easy Facts About Motorcycle Parts New Zealand Specialists Shown4 Simple Techniques For Motorcycle Parts New Zealand SpecialistsAll about Motorcycle Parts New Zealand SpecialistsThe Best Guide To Motorcycle Parts New Zealand SpecialistsEverything about Motorcycle Parts New Zealand Specialists9 Easy Facts About Motorcycle Parts New Zealand Specialists Described

Get to out to one of our specialists today.CNC machining technology is quickly ending up being the focal factor of several various manufacturing processes around the world as a straight outcome of its several advantages over various other techniques. Furthermore, the markets that produce motorbikes have gotten on board with this fad. One of the most innovative business are now creating their engine components and wheels using machining strategies originally developed for motorcycle parts.

On the other hand, the results of industry are the key focus of this write-up. Allow's get right into it. You may be wondering why we make use of. It is not tough to fathom the variables that brought about this outcome. Now that we have your attention let us explain the rationale behind this modern-day advancement in the motorcycle production market.

Top Guidelines Of Motorcycle Parts New Zealand Specialists

In addition, you have complete control over the look of the parts, even down to the minute information. Periodically, motorcyclists may choose to spruce up their ride by setting up aftermarket components or changing the bike's transformation.

The Facts About Motorcycle Parts New Zealand Specialists Uncovered

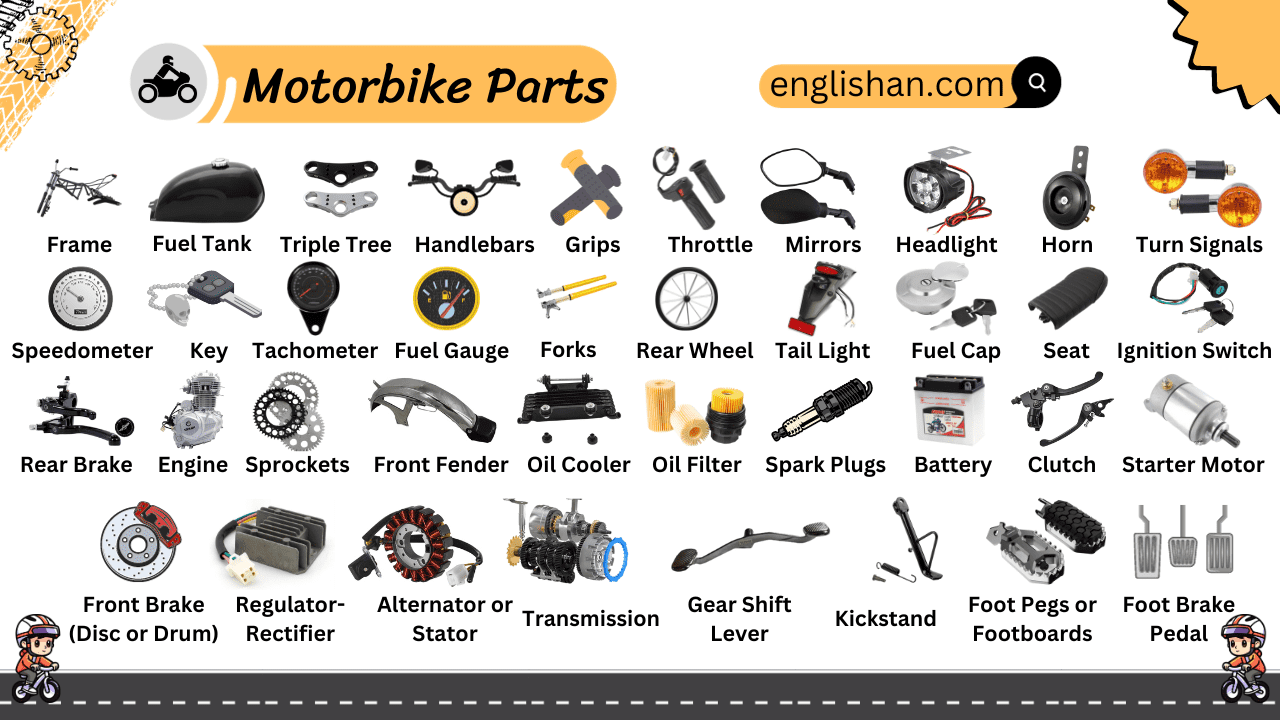

CNC machining may be made use of to make nearly all of a bike's metal and plastic components. To proceed, we'll discuss numerous machined parts for motorbikes. As opposed to those on cars and trucks, wheels on motorcycles have a tendency to be a lot more apparent. As a result, the bike's looks may be boosted with the appropriate modification of these wheels.

When tailoring the wheels, the disks are where the focus needs to be. Most of them are made out of aluminum. Light weight aluminum alloys are widely known for the superior machining capacities that they have. Milling treatments are made use of to get the wanted degree of wheel customization. An additional aspect of the bike that might be personalized is the tires.

Motorcycle Parts New Zealand Specialists Can Be Fun For Anyone

When it concerns a vehicle (or a motorcycle), the most crucial component is the engine. A number of people mention it as the "heart" of the vehicle. On the various other hand, the camshaft, the cylinder head, and the pistons have a tendency to be elaborate and require layouts with a high level of precision.

Lights is an additional facility aspect of modification. Usage just high-grade products, nonetheless, considering that these lights are crucial for the safety and security of motorcyclists and other drivers or individuals on the road, especially during the night. Motorbike fronts lights have 3 main components: the light bulb, or light, the lens, and the housing. Particularly, we customize the lens and the housing.

Milling procedures with a remarkable coating would lead to the lenses having a reflective top quality that is similar to that of a mirror. The cover, on the various other hand, is not composed of fragile products; rather, it is created out of tough polymers that can be machined into more complex patterns.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

Motorbike producers typically cast these components, however just for the manufacturing of bespoke parts. Machining on 5 axes in today's world is the methods by which any style form may be recognized.

The success of the procedure is contingent on the mill cutters' capability to compute subtle and difficult angles properly. Choose Runsom for your customized bike components! We have the capability to fabricate complex and fashionable components making your bike incomparable. A lot of are crafted from aluminum or steel alloys, each of which has its uses and benefits.

Right here are a few instances of steels commonly used in motorbike component machining. Light weight aluminum is the key material used by business concentrating on generating custom bike components to produce most of these parts. In the past, we would build our engines out of cast iron. On the other hand, light weight aluminum is promptly becoming the description product of selection, partially due to the fact that it is more light-weight.

Zinc refers to another steel that is extremely light in weight and has excellent machining top qualities because of its high mechanical strength. This material might be developed right into nearly any shape and keeps its measurements well. Also mission-critical components that require a high level of precision may benefit from their use.

Little Known Questions About Motorcycle Parts New Zealand Specialists.

Another metal that sees heavy usage in the production of CNC-customized components is magnesium. It is among the lightest metals that are now available and has exceptional machinability functions and stamina proportionate with its reduced weight. Among the downsides of magnesium is that its dust may easily catch fire.

Their most typical use in producing numerous motorbike components is fasteners, such as screws and screws. Their reduced susceptibility to oxidation and rust makes them excellent for this usage.

Fascination About Motorcycle Parts New Zealand Specialists

It appears that CNC transforming and milling are the foundational procedures. Alternate strategies exist, such as drilling. Allow's examine a number of these machining methods detailed. The CNC transforming method is taken into consideration a subtractive manufacturing method. In addition, it requires keeping bars of material, usually plastic or metal, ready and afterwards twisting a cutting tool to remove areas of the product try this site as the product is transformed.

These approaches are equally essential and produce parts with high precision and constant top quality. The processes assist improve the total high quality of the machined bike components.

The Best Strategy To Use For Motorcycle Parts New Zealand Specialists